Our R&D services are individually tailored to fit each project and ultimately reach our customer’s goal in the most efficient way. We see our customers as partners and continuously engage in a culture of active and open communication.

The unique BioNavigator® toolbox utilizes our extensive in-house libraries and metagenome databases to compile a panel of enzymes specialized to your reaction. We then screen the compiled enzyme panel in our laboratories under your desired final process conditions. Finally, we select the best enzymes, characterize and provide these to you for in-house testing.

In iterative cycles of computer aided directed evolution, we generate enzymes with unmet performance, tailored to your needs. The BioEngine® combines comprehensive in silico studies and experimental screening of enzyme libraries in every round of evolution. Predicted combinations of critical residues for the enzyme’s activity are used to create small libraries, which are screened for improved enzyme variants. Our smart libraries allow the use of high throughput GC and HPLC analytics measuring the real reaction components and giving detailed insights to each reaction.

We offer optimization of reaction conditions, shortening of the time to market, and development of a complete process including downstream processing and scale-up to a 10 L reaction scale.

In our facilities, we can develop fermentation processes and manufacture enzymes in an up to 5000 L scale.

Each project is assessed for feasibility considering technology- and cost-aspects and openly discussed with our customer to ensure that we provide the best possible service.

We update the customer regularly during our screening and evolution phases on the progress and latest developments of the project.

We can develop an optimal industrial process together with our customers to maximize the projects outcome.

Each project is assessed for feasibility considering technology- and cost-aspects and openly discussed with our customer to ensure that we provide the best possible service.

We understand the needs of our customers. Although our core services around enzyme screenings and enzyme evolution will always give the best results, some customers may need a faster option. Therefore, we offer in addition to screening services customized enzyme kits that are the best compromise between the thoroughness, range and success rate of an enzyme panel screening and the short-term availability of an enzyme kit. This allows our customers in the fast-moving markets to react in time while maximizing their chances.

Our general enzyme kits, provide a selection of enzymes covering a broad range of properties to best suit a general screening for active enzymes for a given substrate or reaction type. All enzymes of our general kits can be supplied at different scales on a €/kg basis.

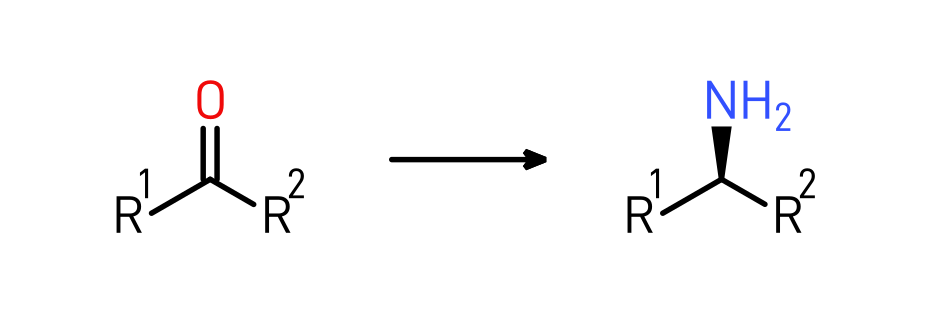

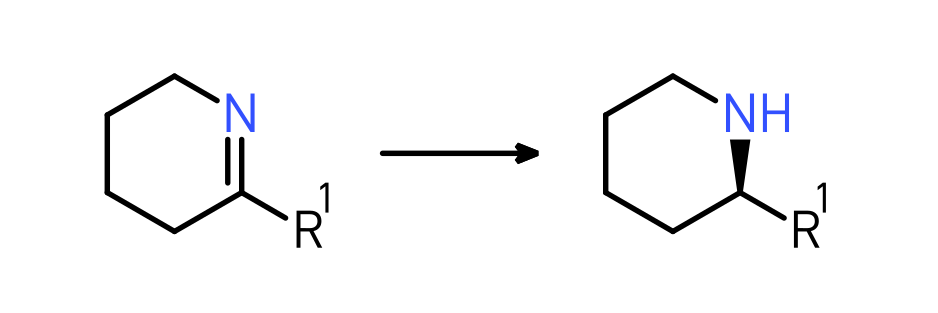

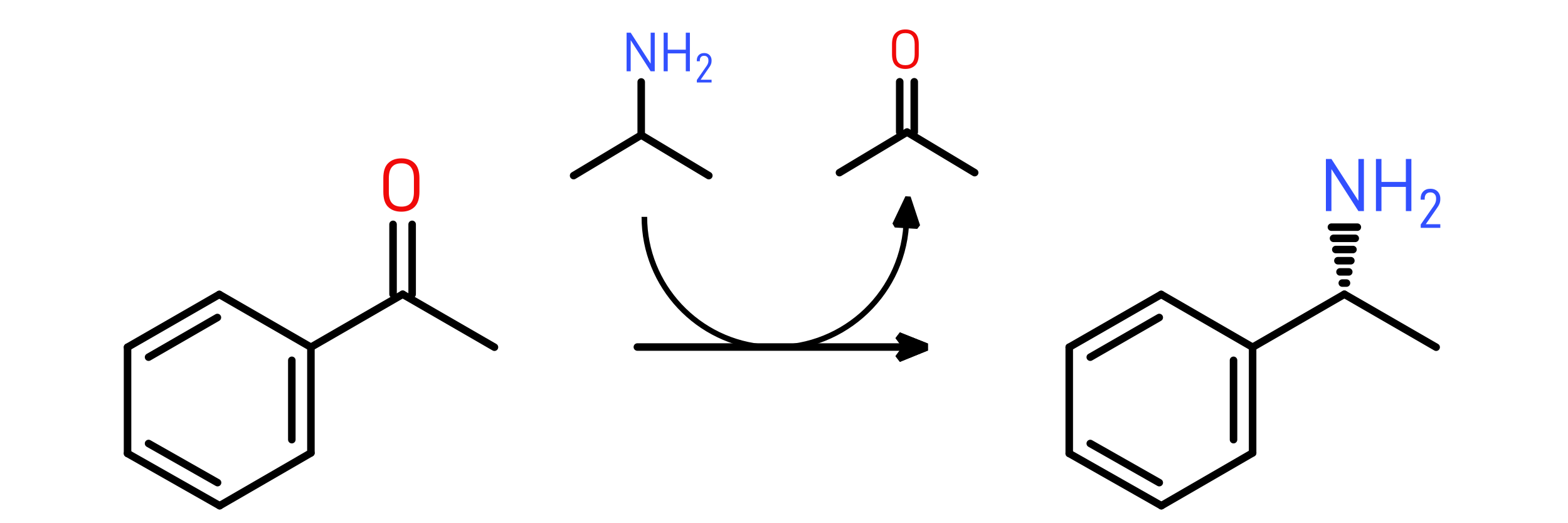

Selection of 20 different natural and engineered transaminases varying in chiral selectivity, stability, solvent tolerance, and substrate scope.

Kit content: 20x 0.5 g enzyme powder (lyophilized crude cell-free lysate)

Selection of 17 different S-selective natural and engineered transaminases varying in stability, solvent tolerance, and substrate scope.

Kit content: 17x 0.5 g enzyme powder (lyophilized crude cell-free lysate)

Selection of 17 different R-selective natural and engineered transaminases varying in stability, solvent tolerance, and substrate scope.

Kit content: 17x 0.5 g enzyme powder (lyophilized crude cell-free lysate)

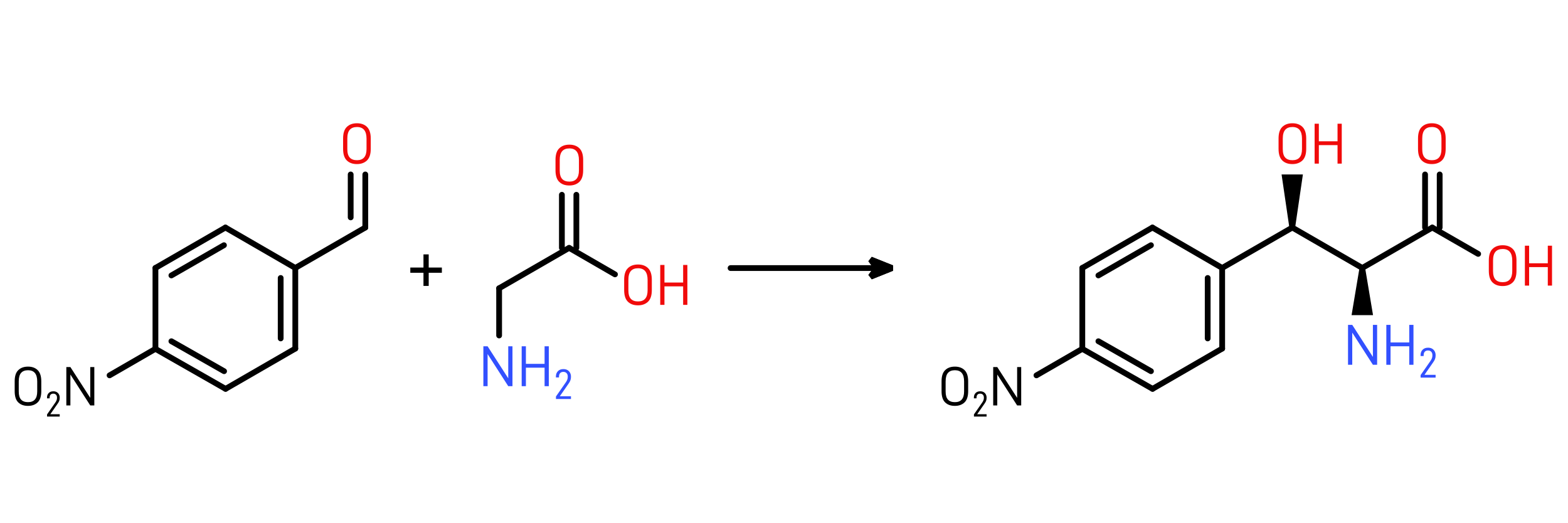

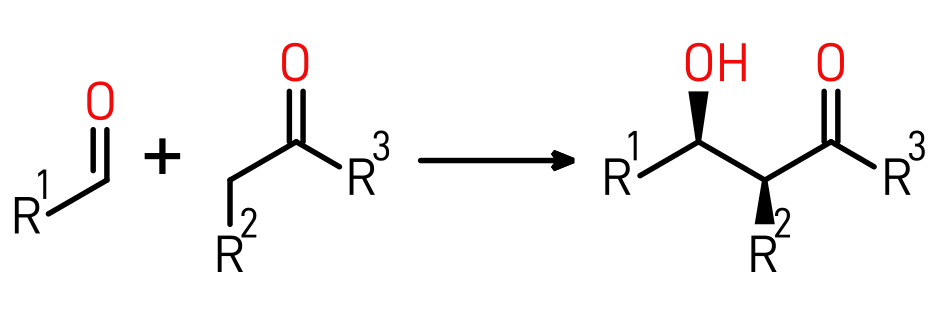

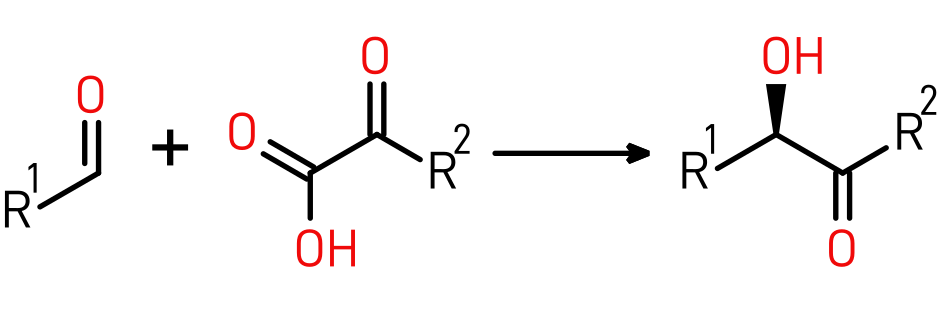

Selection of 20 different natural and engineered L-threonine dependent aldolases varying in chiral selectivity, stability, solvent tolerance, and substrate scope.

Kit content: 20x 0.5 g enzyme powder (lyophilized crude cell-free lysate)

Selection of around 20 different natural and engineered transaminases varying in selectivity, stability, solvent tolerance, and substrate scope.

Kit content: 20x 0.5 g enzyme powder (lyophilized crude cell-free lysate)

Enzymes are selected by in silico analysis of the substrate in combination with our enzyme library to select the most suitable enzymes for your desired target. Contact us to see if we can offer an enzyme selection tailored to your specific substrate!

Customer requirement: Disclosure of transformation/substrate for in silico analysis.

Kit content: 10x 0.5 g enzyme powder (lyophilized crude cell-free lysate)

Enzymes are selected for our enzyme library on a knowledgebase (no in silico analysis) with rough description of the target substrate or reaction (e.g. bulky, aromatic, alkyl chain, functional groups). Contact us to see if we can offer an enzyme selection tailored to your specific substrate!

Customer requirement: Rough description of transformation/substrate properties. No disclosure of the complete substrate required.

Kit content: 10x 0.5 g enzyme powder (lyophilized crude cell-free lysate)

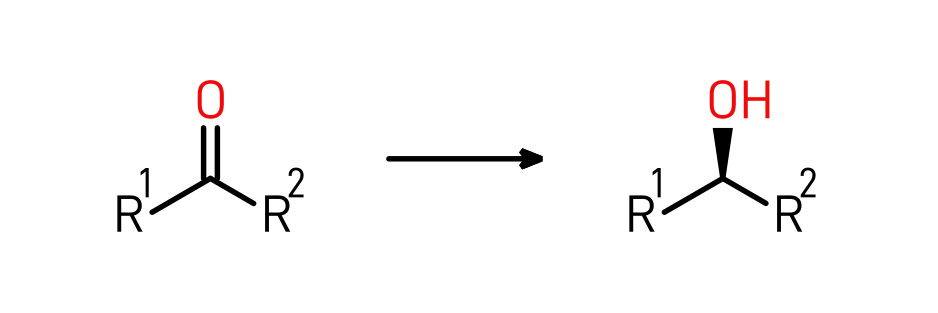

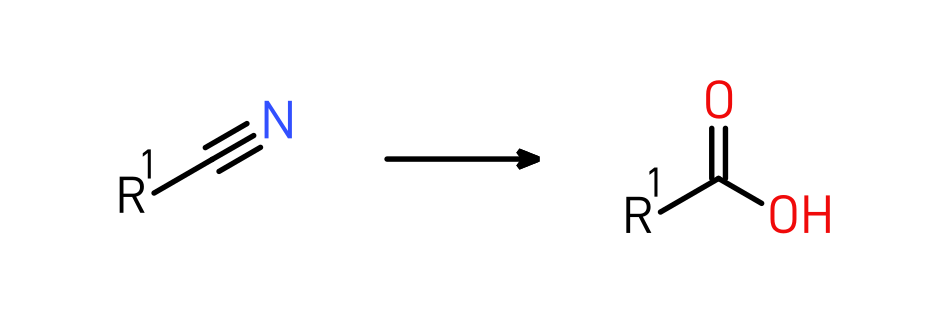

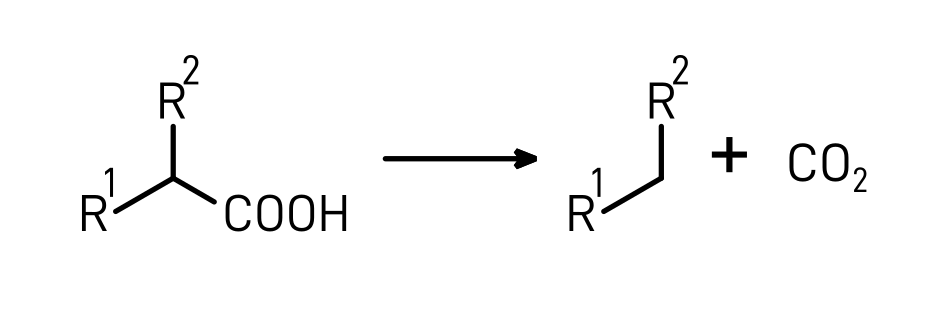

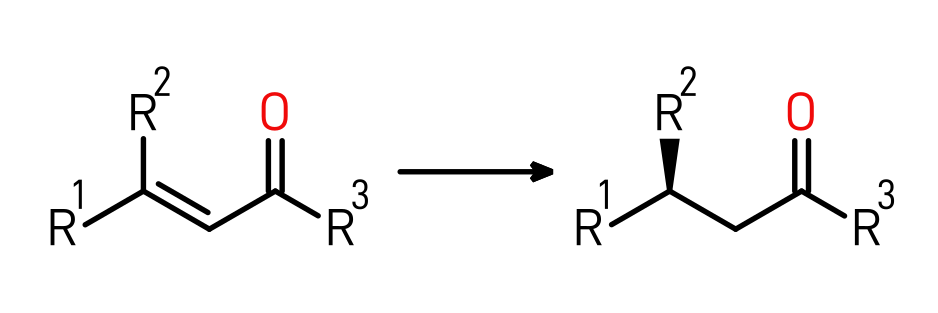

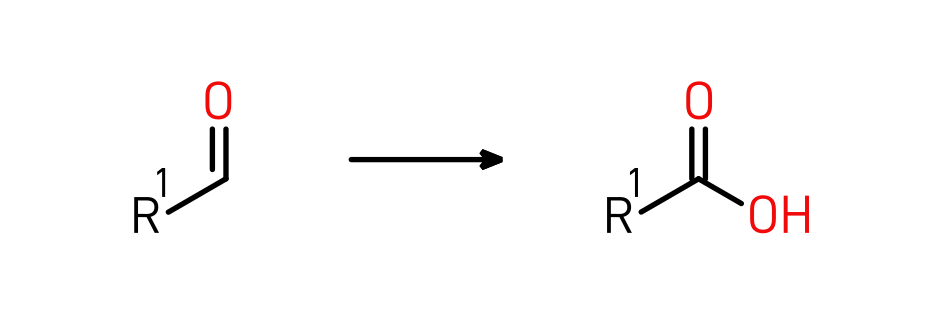

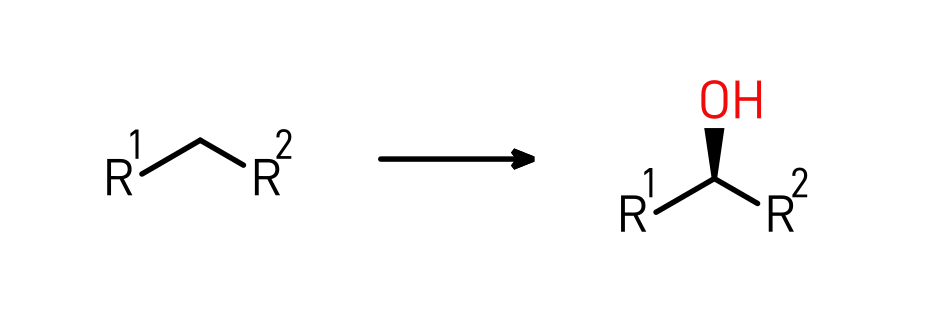

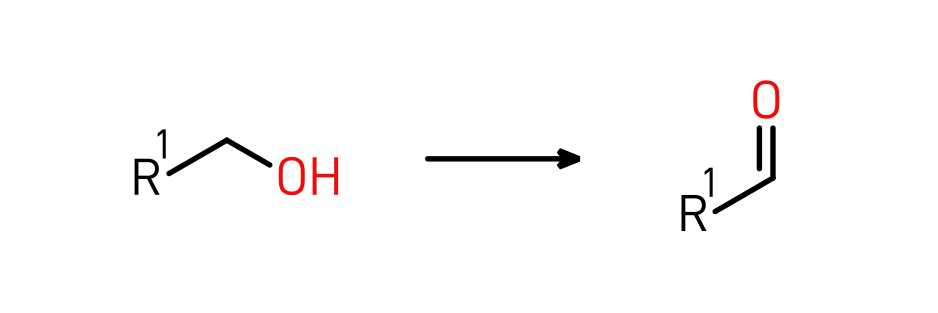

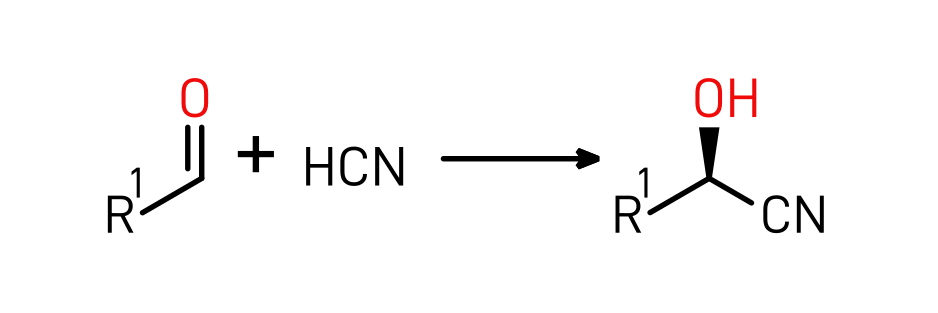

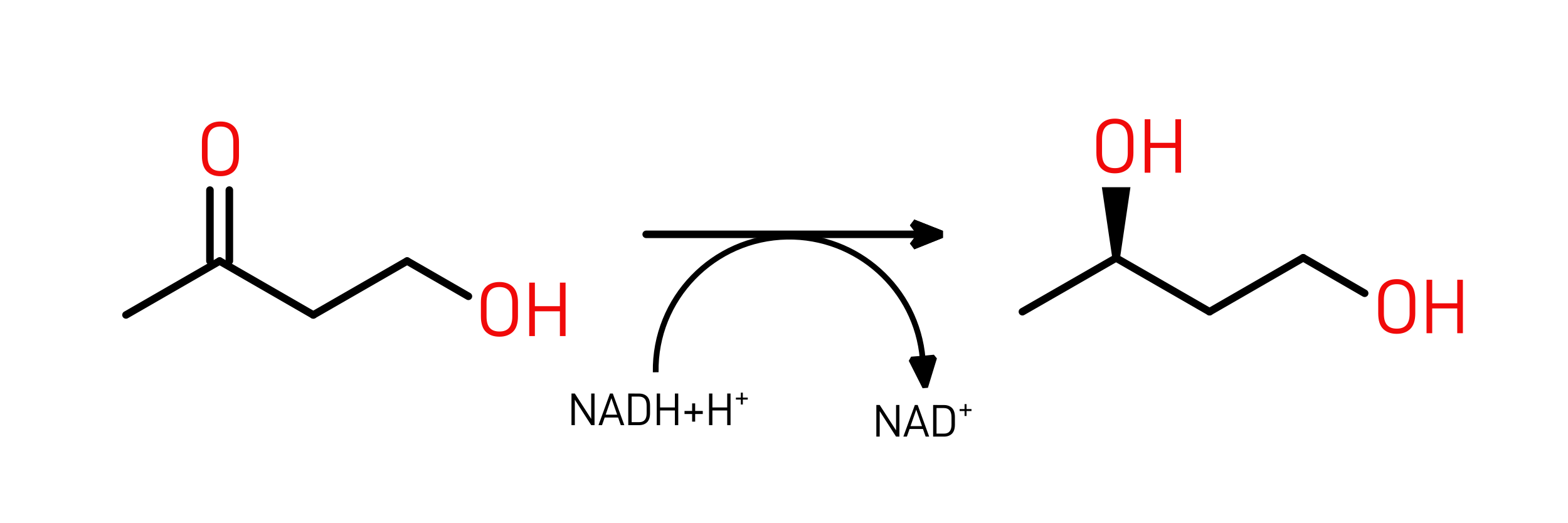

Our technology and R&D services can make virtually any process more cost efficient and more environmental friendly. We are experts in finding biocatalytic solutions for the most important chemical transformations, ranging from RedOx chemistry to C-C bond formation.

Wildtype Enzyme:

Industrial Enzyme:

Industrial Enzyme: